The important facts you need to know!

When shopping for synthetic grass products for supply or installation, it is important to know all the facts and purchase a product better designed for your individual needs. We've put together this buyers guide based on facts to better explain the differences in synthetic turf, infill products, installation methods, and warranties.

Is it worth it to purchase a less expensive artificial turf or have it installed by an inexperienced landscaper?

Although the thought of saving a few hundred or thousand dollars up front might be tempting, going for the synthetic turf that is of inferior quality could cost you big time down the road. Cheap synthetic turf will more than likely turn out to be far from the cheap solution you originally thought it was going to be. Ask yourself would you hire a landscaper to install carpet in your home? Poor turf installations can cost thousands of dollars to repair, if its done right the first time your investment will bring you a lifetime of enjoyment and satisfaction.

Although the thought of saving a few hundred or thousand dollars up front might be tempting, going for the synthetic turf that is of inferior quality could cost you big time down the road. Cheap synthetic turf will more than likely turn out to be far from the cheap solution you originally thought it was going to be. Ask yourself would you hire a landscaper to install carpet in your home? Poor turf installations can cost thousands of dollars to repair, if its done right the first time your investment will bring you a lifetime of enjoyment and satisfaction.

To properly evaluate a company and its products you should look at these four main components:

1.) The construction of a product consists of its yarn and its primary and secondary backing.

|

Yarn Technology & Shapes:

|

Definitions:

Density/Face Weight:

- Yarn: The grass fibers which are tufted into the primary backing.

- Tuft: Process in which all yarn material is woven into the primary backing.

- Primary Backing: First layer(s) of material used by all turf manufactures to tuft yarn.

- Secondary Backing: There are many types of secondary backing on the market but the most common for residential, commercial, and pet applications consist of a urethane coating (industry standard is 20 oz. per square yard).

- Tuft Lock Strength: How much force needed to pull out yarn fibers when completed (industry standard is 8 lbs of force).

- Infill: Infilling is the process of adding a quality granule on top of the surface to fill out the space between the turf blades. The granules add durability to the surface while it supports the fibers and resists matting.

- Pile Height: The height of the pile or yarn that rises above the turf backing.

Density/Face Weight:

- Face weight is a industry wide used term to describe the amount of material tufted into the primary backing of the product. Generally, the higher the face weight is, the thicker, fuller, and more durable the product is. It is also a determining factor in the final price aside from yarn material, quality, and backings.

- 30-48 oz.: Products in this category would be considered economy or entry-level products. The lower density is ultimately going to be less durable, but far less expensive. These products work well for enhancing the appearance of low traffic areas and require 2 - 4 lbs. of quality infill depending on the pile height of the turf and other variable factors.

- 50-60 oz.: These products are considered medium density and are also priced accordingly. They can work well for moderately used commercial and residential properties and require 1.75 - 2.5 lbs. of quality infill. These synthetic grass products look great but if overused matting can occur.

- 62-82 oz.: These would be your higher end turf product lines with a more natural appearance. The higher density and secondary thatch means these products could be installed with only using 1.5 - 2 lbs of quality infill. Infilling them will even further increase the durability of the product making them the choice for high traffic areas and pet solutions.

You should know that there are three types of Synthetic Grass Yarns:

What is a Permeable Backing?

Permeable Backing is a backing in which allows water to drain through by either cloth or perforated holes.

Perforated holes type backing; Is also called Urethane Backing.

Duraflo (Geo-textile Cloth) Type Backings:

Testing the Tuft Lock Strength:

2.) Evaluating the installation techniques & seaming procedures of a company.

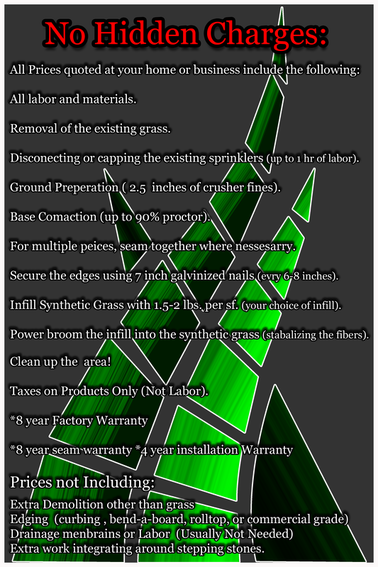

Turf by Design's Professional Installation Guidelines

3.) Infill is the material used to support the blade fibers therefor increasing the lifespan of your investment.

4.) Warranty & Reputation.

- Polypropylene (PP)- is the least expensive yarn, which makes it the artificial turf the majority of deal-shopping homeowners will choose. Unfortunately this is a poor purchasing decision, as polypropylene artificial turf has a low melting point, and always wears out easier than the other materials you have to choose from. This material is used most often for sand filled golf putting greens.

- Polyethylene (PE)- synthetic grass is known for its soft texture, life-like looks in a home landscaping installation and is widely used on soccer fields, football fields, and landscape design. High quality polyethylene synthetic grass is just right for your yard with the look and feel of that high cost, high maintenance and water guzzling natural grass. You can’t go wrong Turf by Designs high performance synthetic grass. In fact, we guarantee it for 8 years!

- Nylon- is the strongest artificial turf yarn available. It can withstand high temperatures and weight, and still retain its original shape. This type of artificial turf is used for high end putting greens because it is durable and creates a perfect environment for practicing your putt as if you were on the greens. It is not used often for landscaping because of the unnatural feel and rough texture.

What is a Permeable Backing?

Permeable Backing is a backing in which allows water to drain through by either cloth or perforated holes.

Perforated holes type backing; Is also called Urethane Backing.

- Comprising a tufted material (primary backing) having melted Polyurethane poured or slurred on top of the primary backing to make the secondary backing. During the hardening process of the secondary backing, holes are extruded in the secondary backing. Urethane backing turf is the most common type of backing in the industry. This turf is specifically perforated with holes engineered to accommodate the normal drainage requirements of rainstorms and snowstorms. Water drains through the small drainage holes into the earth at a rate of 32 inches/hour. This type of turf has a tuft lock strength of at least 8-10 pounds in accordance with the tuft lock test of ASTM-D 1335. The fibers will usually break instead of pull out. Perforated systems have been the standard for turf drainage in Europe and the United States for over 20 years.

Duraflo (Geo-textile Cloth) Type Backings:

- Comprising a tufted material having a hot melt polyethylene adhesive applied to a back side of the stabilized primary backing and adding a Geo-textile fabric which is the secondary backing at a rate of no more than about 12 oz/yd2, wherein the turf has a tuft lock strength of at least 8 pounds in accordance with the tuft lock test of ASTM-D 1335 and a water permeability of at least 100 inches/hour. In addition polyolefins absorb almost no moisture, as compared to other backing adhesives such as urethane and latex, which absorb as much as 5% to 6% of their mass. Absorbing and releasing water leads to expansion and contraction of the turf product as ambient conditions change. With the DuraFlo system, this creeping effect is negligible, and therefore makes a more stable turf system and puts less stress on seams. Furthermore, this process is relatively tension free. The non-woven Geo-textile secondary backing component of DuraFlo is produced in a manner that the fibers are arranged in a random manner, giving isotropic properties for strength and elongation. This adds yet more dimensional stability. DuraFlow is also the only turf backing on the market that is 100% recyclable. It has been used in the United States for the better part of a decade.

- BEWARE!!! The cloth backing will hold pet odors regardless of your infill choice.

- Attached foam cushion backing are a great product for playground use. These attached cushions can help soften the surface underfoot. The cushions are perforated similar to the way urethane backings are perforated. Cushion backings are also being found on the back of putting green products as a way to make new-age greens more receptive to long-distance shots.

Testing the Tuft Lock Strength:

- If the backing of the turf is white (latex) or clear (poor quality urethane) and the fibers pull out easily "BEWARE".

- The turf lock is a very crucial part of the whole system. A simple yet very effective way to test the tuft lock is to try to pull out multiple fibers out from both the top and backside. If they pull out easily it's probably not going to be a good investment. Low Quality Product + Poor Tuft Lock = System Failure

2.) Evaluating the installation techniques & seaming procedures of a company.

- Base Construction and the excavation process is a very critical part of the installation process; the base layer is the foundation and drainage system for your synthetic grass lawn or putting green. When the existing grass and weeds are not removed properly and enough material is not remover weeds and grass will in fact grow right back. it is critical that during the excavation process all the organic material is removed including the root zones. The Sub-base layer is just as important and acts as the foundation for the entire synthetic grass system. A solid foundation is critical to maintaining a nice appearance.

- When the wrong sub-base is used or the base layer is not installed or compacted properly it can lead to poor drainage, lumpy appearance, standing water, and costly repairs.

Continue reading for Turf by Designs General Installation Guidelines!

- In some cases the seams will be the weakest point in your lawn, and it is very important to pay close attention to the way companies bind their products together and what measures they take to ensure a quality install. Many companies use weed fabric and inexpensive glues or regular (indoor) carpet seaming material and or fabric staples to bind their seams together. These installation methods are proven to lead to seam failure "BEWARE".

- Turf by Design uses STA 1000 which is specially formulated "Synthetic Turf Adhesive" to bind artificial grass together to create a durable seamless appearance. STA 1000 is well known in the industry for sports field applications and is proven to be the strongest bonding agent on the market.

Turf by Design's Professional Installation Guidelines

- Ideal Conditions: Turf by Design synthetic grass should be installed during dry conditions with a minimum temperature of 50 degrees Fahrenheit.

- Irrigation: Sprinkler systems are no longer needed with Turf by Design synthetic grass; although in some cases they may be needed to water plants, shrubs, and trees within the vicinity. Turf by Design can make the alterations for an additional cost. If you have a drip system in place it is safe and advised to cap them off. You can save up to 70% off your water bill.

- Excavation: Turf by Design will excavate any sod and weeds up to 4 inches as well as other debris and materials in the designated installation area (4 inches from final grade). The old sod will be hauled away to a recycling center or landfill and disposed of.

- Base Construction: Compact and smooth the existing grade as needed. The purpose of the sub-base material is simple; it is the foundation and drainage for the artificial turf system, while providing a solid ground to walk on. 3 - 4 inches of crusher fines (grey breeze) with a 90% compaction is required. It is important to maintain a minimum grade of 2% to allow for proper drainage.

- Compaction: Using a heavy duty roller or plate compactor type tool, we will tightly compact the sub-base up to 90% proctor. The goal is to have the sub-base as smooth as possible, yet solid when walked upon.

- Synthetic Grass Installation: Roll the Turf by Design synthetic grass out on top of the constructed based, as planned. If the site requires multiple roll widths, the grain of the fibers on each roll of turf will run the same direction. Install Synthetic Grass and custom fit to the desired area using the latest tools and equipment.

- Seaming: If seams are required we will use STA 1000 method, this is the strongest artificial turf bonding agent on the market. Alternative seaming methods will not be permitted with Turf by Design synthetic grass applications.

- Securing the Perimeter: Each installation is unique depending on the surface we are butting the synthetic grass up to numerous methods will be performed for added security to the perimeter edges. Typically we tuck each edge and use 8 inch galvanized nails every 6-8 inches around the edges to secure it down to the ground (in higher traffic areas more will be added for additional stability).

- Infill: 1.5 - 2 pounds of infill is recommended per sq. ft. for performance and durability. Infill helps weigh the turf down as well as help keep the turf fibers from matting down. In higher traffic areas more infill may be used to increase the life of your artificial grass.

- Power Broom: Using a motorized rotary broom it will quickly and efficiently fluff up the turf fibers and work in the infill material evenly in-between the blades of grass, instantly bringing your new synthetic grass lawn to life!

- Cleaning: Using a power washer, leaf blower, and other cleaning tools we can quickly clean up the area leaving you with a beautiful new landscape you can finally enjoy.

3.) Infill is the material used to support the blade fibers therefor increasing the lifespan of your investment.

- Infill is applied to the surface of the turf, and then a power broom is used to work the material between the blades. Just like the artificial turf selection it is important to make sure proper infill material is used during the installation.

- Zeofill is and is the most advanced infill system you can use for pet use applications. ZeoFill is recognized as the best all natural artificial grass infill. When used on artificial or synthetic lawns it neutralizes the ammonia in pet urine and eliminates the odor. It is recommended to use all ZeoFill as your infill on top of the turf when medium to large sized pets are going to urinate on the turf. ZeoFill also retains water longer than other infill products and helps to keep the grass up to 20 degrees cooler. It is also 100% natural and non-toxic! (Read more about ZEOFILL)...

- EnviroFill is a coated Silica Sand, but because it is a coated sand the silica dust particles are almost non-existent, making it a safer product. Generally, coated sand granules are sealed and therefore non-porous, are safer for playgrounds and backyard solutions. EnviroFill is generally round in shape, making it far less abrasive. The biggest benefit of coated sand is that generally green in color, which means it hides well in the thatch and also reflects far less heat. The product can be up to 20% cooler than other infill products.

- Sand is commonly used, and is a far less expensive option for synthetic turf installs. It is typically a light tan color that enhances the tan thatch in the more natural style products. When sand is used for infill it is critical that the right type is used. Most sand on the market today have course features that can actually damage the turf fibers and lead to per-mature wear, so make sure a good quality industry approved rounded sand (16/30 mesh is the best). Angular sand (Example~ Play Sand / Mason Sand) will damage the fibers and void the manufacturers warranty. Sand Infill is not recommended for pet applications and may need chemical treatments to cover up odors. For pet solutions use Zeofill!

- Crumb rubber is most commonly used for sports applications due to the softer feel and natural ball roll . The rubber comes from recycled tires, and does not compact to a hard base to prevent drainage. It retains heat and can reach temperatures of 165 degrees in the summer months.

- "BEWARE" Some Companies insist on NOT using infill at all, these installations can easily be identified as the turf tends to mat down and wrinkle. Manufacturers across the country recommend using 1-3 lbs of infill per sf. for landscape turf and up to 5 lbs for sports turf systems. The infill is the support system for the turf blades keeping them vertical and it increases the overall durability. Infill also weighs down the turf to prevent shifting and movement that leads to costly repairs and system failures.

4.) Warranty & Reputation.

- Federal law requires that warranties be available for you to read before you make your purchase.

- "BEWARE" Oral Promises; If a salesperson makes a promise orally, such as that the company will provide free repairs, get it in writing. Otherwise, you may not be able to get the service that was promised.

- When studying a warranty, look for two things; the length of warranty and what is exactly covered under the warranty as it pertains to the product and installation. Although synthetic turf for the most part is extremely durable, there are circumstances in which the consumer will want to be protected. Seam rupture, fiber defects, and UV fading are all problems that may arise during the manufacturing process and the life of the product. Consumers should research which companies offer protection against these issues before making a decision. Turf by Design only uses First Quality products (NO SECONDS) and we back every project with an 8-10 year warranty on turf products and 2 years for installations. With Turf by Design you are 100% covered with a rock solid warranty!

- At Turf by Design we stand for integrity and are committed to installing the best product at the lowest price possible. There are many companies in the synthetic grass market; none offer the level of quality and service that Turf by Design can provide. You will be certain that you are dealing with a reputable company that has over a decade of installation experience. We are dedicated to you, proud of our work and the best in the business! Learn more about Turf by Design...

Still Have Questions? We've Got Answers! <--- Click for Frequently Asked Questions

If you are looking for the highest quality LEAD FREE synthetic grass for commercial and residential lawns, look no further than Turf by Design! "Safe, Clean, and GREEN Synthetic Grass Solutions"